Gluing

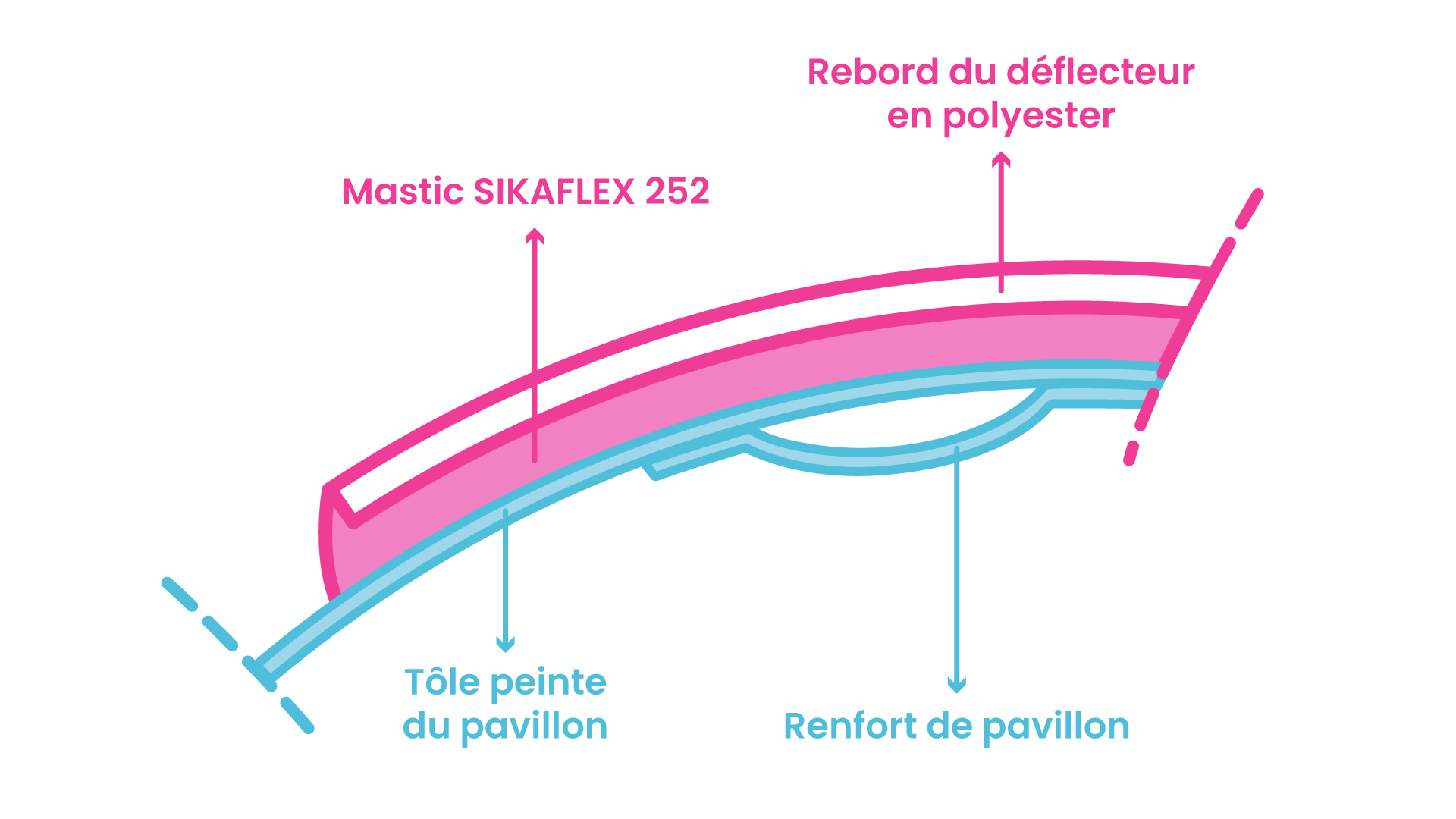

The disappearance of rain gutters (water spouts) in the design of cars and truck cabins for the sake of manufacturing convenience and, at the same time, improved aerodynamics has led to a new technique of fixing deflectors by adhesive bonding to the roof.

NOVI, in collaboration with industrial bodybuilders, performed its first adhesive bonding with polyurethane sealant as early as 1994.

Since that date, more than 100,000 NOVI bonded deflectors have been in circulation in Europe.

2 RULES TO FOLLOW

1) TEMPERATURE/span>

Do not work below 12°C. It is important to note that below 8°C, polyurethane remains inert in its setting, with polymerization only occurring with ambient humidity and temperature.2) CLEANLINESS

No adhesion is possible on a dirty, greasy, or dusty surface. Perfect cleanliness is a guarantee for effective bonding.SIKAFLEX 252 POLYURETHANE SEALANT CHARACTERISTICS

Density: 1.16

Shore hardness: approx. 55

Polymerization rate at 20°C: 4mm/day

Service temperature: -40°C to +90°C

Mechanical performance on polyester: approximately 30 kg/cm2

Flexibility: 300%

SIKA CLEANER 205 PRIMER CHARACTERISTICS

(adhesion promoter used as a primer and degreaser)

Density: 0.79

Consumption: 20 to 50g/m2

Drying time: 2 to 5 minutes

Operating temperature: +5°C to 35°C

CONSUMPTION

An extruded sealant cord with a 9mm diameter allows for a bonding joint of 3×20 over 5 linear meters.

Technical

NOTE

It is essential for the polyurethane sealant to have a sufficient thickness to act as an elastomer.

If you secure the deflector with a strap, make sure not to force out the sealant by applying excessive pressure, which could cause the deflector to adhere to the roof sheet.

- Allow at least 12 hours of polymerization before delivering the vehicle.